Manufacturing is undergoing a seismic shift, driven by the emergence of Vertical AI—a branch of artificial intelligence tailored to meet the unique demands of specific industries. In contrast to horizontal AI, which offers generalized solutions across various sectors, Vertical AI hones in on the particular challenges and opportunities inherent in an industry like manufacturing. This targeted approach allows for deeper integration and more impactful outcomes, reshaping traditional manufacturing processes in unprecedented ways.

Manufacturing, with its heavy reliance on data, precision, and optimization, is a prime candidate for disruption by Vertical AI. The sector has long been known for complex workflows, equipment-intensive operations, and intricate supply chains—all of which can be optimized by leveraging AI-driven insights. Whether it's predictive maintenance to reduce machine downtime, supply chain optimization to enhance efficiency, or quality control powered by AI-based visual inspection, Vertical AI is revolutionizing how manufacturers operate.

This shift towards AI-driven solutions is not just about automation—it's about transforming the very fabric of manufacturing processes. With AI, factories are becoming smarter, supply chains more resilient, and production lines more efficient. Companies leveraging Vertical AI can gain a significant competitive advantage by improving operational efficiency, cutting costs, and boosting product quality.

Leading the charge in this transformation are startups spotlighted by Institutional Venture Partners (IVP), who are focusing on AI solutions specifically designed for the manufacturing industry. IVP’s investments highlight the importance of domain-specific AI in industries where precision and customization are paramount. With the rapid pace of technological advancement, Vertical AI is not just an option for manufacturers—it’s becoming a necessity for those looking to remain competitive in a fast-evolving global market.

As we delve deeper into the world of Vertical AI in manufacturing, we’ll explore how these specialized AI solutions are reshaping the landscape, the key startups driving innovation, and the challenges and benefits that come with this technological evolution.

2. What is Vertical AI in Manufacturing?

Vertical AI refers to artificial intelligence systems that are designed specifically for a particular industry or sector, unlike horizontal AI, which provides broad solutions that can be applied across multiple industries. In the context of manufacturing, Vertical AI is uniquely positioned to tackle industry-specific challenges, such as optimizing complex supply chains, enabling predictive maintenance, and advancing smart factory automation. The ability to tailor AI solutions to the precise needs of manufacturing gives Vertical AI a distinct advantage over more generalized AI systems.

Manufacturing is characterized by its reliance on precision, efficiency, and optimization. From managing the flow of raw materials through global supply chains to maintaining high standards of product quality, manufacturers deal with vast amounts of data and complex workflows. Vertical AI addresses these challenges by leveraging advanced algorithms and machine learning models to extract actionable insights from real-time data. This results in more efficient processes, reduced downtime, and higher productivity.

For example, supply chain optimization is a key area where Vertical AI excels. Traditional supply chains are prone to inefficiencies, including bottlenecks, inventory mismanagement, and unpredictable disruptions. AI systems tailored for manufacturing can analyze supply chain data in real time, predict potential issues, and automatically adjust workflows to maintain smooth operations. This allows manufacturers to reduce waste, improve resource utilization, and respond more effectively to market demands.

Another critical area is predictive maintenance. Manufacturing machinery is often subject to wear and tear, and unexpected equipment failures can result in costly downtime. Vertical AI solutions, designed specifically for manufacturing environments, use sensors and data analytics to predict when machines are likely to fail. This enables companies to perform maintenance proactively, rather than reactively, minimizing disruptions and extending the lifespan of equipment.

Smart factory automation is another transformative use case for Vertical AI. As part of the broader Industry 4.0 movement, smart factories utilize IoT (Internet of Things) devices, robotics, and AI to create highly responsive and adaptive production environments. Vertical AI plays a central role in processing the massive amounts of data generated by these connected devices, allowing manufacturers to optimize production schedules, enhance product customization, and increase overall flexibility.

In contrast to horizontal AI, which might provide general machine learning algorithms applicable across sectors, Vertical AI in manufacturing leverages deep domain expertise, focusing on the unique regulations, workflows, and technical requirements of the industry. This specialization enables AI solutions to integrate seamlessly with existing manufacturing systems, provide more accurate insights, and deliver a higher return on investment.

By addressing the specific needs of manufacturers, Vertical AI is driving the next wave of innovation in the industry, helping companies stay competitive in an increasingly dynamic global market. Whether through optimizing supply chains, improving machine uptime, or automating factory operations, the impact of Vertical AI is both profound and far-reaching.

3. IVP’s Insight on Vertical AI in Manufacturing

Institutional Venture Partners (IVP) has been at the forefront of fostering innovation through Vertical AI across various industries, including manufacturing. The firm’s investment strategy focuses on startups that apply AI-driven solutions to specific sector challenges, and manufacturing is no exception. According to IVP, the future of manufacturing lies in the integration of Vertical AI technologies, which can enhance automation, real-time analytics, and robotics, helping manufacturers achieve greater efficiency and competitiveness.

One of the key trends IVP highlights is the shift towards automation in manufacturing. While automation has been a cornerstone of manufacturing for decades, Vertical AI takes it a step further by enabling more precise and adaptive processes. For instance, AI can now predict equipment failures with high accuracy, optimize production schedules in real-time, and streamline complex workflows. This level of automation significantly reduces downtime and improves overall production efficiency, leading to cost savings and faster time-to-market.

Another trend emphasized by IVP is the growing importance of real-time analytics. Modern manufacturing facilities generate vast amounts of data, from machine sensors to supply chain tracking systems. Vertical AI startups are building solutions that can analyze this data instantly, providing actionable insights that help manufacturers make more informed decisions. These insights can range from optimizing energy consumption to improving product quality, giving manufacturers the agility they need to respond to changing market conditions.

Robotics, driven by AI, is also a key focus area for IVP’s vision of the future of manufacturing. AI-powered robots are being deployed in factories to handle tasks that require a high degree of precision, speed, and adaptability. These robots can work alongside human operators, learning from their environment and making adjustments on the fly to improve efficiency. Vertical AI enhances the capabilities of these robots by enabling them to integrate with broader manufacturing ecosystems, including supply chain management and quality control systems.

Through its investments, IVP sees a clear opportunity for Vertical AI to transform the manufacturing sector by addressing long-standing inefficiencies and enabling more agile, data-driven operations. Startups that focus on these trends—automation, real-time analytics, and robotics—are poised to lead the next wave of innovation in manufacturing, helping companies stay competitive in an increasingly complex and fast-paced global market.

In particular, IVP’s approach to investing in Vertical AI startups aligns with the broader trend of Industry 4.0, where digital transformation, data analytics, and intelligent automation are becoming central to manufacturing. By supporting companies that specialize in sector-specific AI applications, IVP is positioning itself as a key player in driving the future of manufacturing innovation.

4. Key Use Cases of Vertical AI in Manufacturing

Predictive Maintenance

One of the most transformative applications of Vertical AI in manufacturing is its ability to predict equipment failures before they happen. Using real-time data collected from sensors embedded in machinery, AI-driven systems can analyze patterns of wear and tear, flagging potential issues long before they lead to costly downtime. This predictive maintenance model not only helps manufacturers avoid unexpected breakdowns but also extends the lifespan of equipment by ensuring that maintenance is performed at optimal intervals.

For example, companies like TRACTIAN leverage Vertical AI to monitor industrial machinery and predict failures. By applying machine learning algorithms to vast amounts of operational data, they can provide manufacturers with actionable insights, allowing for targeted maintenance that minimizes interruptions to production. Predictive maintenance represents a significant shift from reactive maintenance strategies, driving substantial cost savings and improving overall operational efficiency.

Supply Chain Optimization

Supply chains in manufacturing are notoriously complex, often spanning multiple geographies and involving countless suppliers, distributors, and logistics providers. Vertical AI has emerged as a powerful tool to optimize supply chains, ensuring that materials are delivered on time, inventories are managed effectively, and production schedules are synchronized across the board.

AI solutions for supply chain optimization use real-time data from multiple sources—ranging from weather reports to supplier performance metrics—to predict potential disruptions and recommend adjustments. Startups like basetwo offer AI platforms designed to optimize supply chains by analyzing data to forecast demand, reduce lead times, and identify inefficiencies. This predictive capability helps manufacturers avoid bottlenecks, reduce waste, and improve delivery timelines, ultimately enhancing customer satisfaction.

Quality Control

Maintaining high product quality is essential in manufacturing, where even minor defects can result in costly recalls or customer dissatisfaction. Vertical AI is revolutionizing quality control processes through advanced automated visual inspection systems. These systems use AI and machine learning models to analyze images and detect defects with greater accuracy and speed than human inspectors.

Companies like EthonAI are at the forefront of applying AI to automate quality control. By using AI-driven image recognition, they enable manufacturers to identify defects in real time, reducing the likelihood of defective products reaching the market. Automated quality control not only improves the precision of inspections but also reduces labor costs and accelerates production timelines.

Smart Factories

The concept of smart factories—where the entire manufacturing process is interconnected and driven by data—is becoming a reality thanks to Vertical AI. These factories leverage IoT (Internet of Things) devices to collect data from every aspect of the production process, from raw materials to finished goods. Vertical AI processes this data in real-time, enabling factories to be more responsive, adaptive, and efficient.

By implementing AI-driven analytics, smart factories can dynamically adjust production parameters, optimize energy usage, and ensure that resources are utilized efficiently. Startups like Leucine focus on integrating IoT with AI to create smart factories that can monitor production environments and provide real-time recommendations for improvement. These AI-driven insights not only enhance productivity but also enable manufacturers to adapt to fluctuations in demand quickly, ensuring faster time-to-market and increased operational flexibility.

These use cases—predictive maintenance, supply chain optimization, quality control, and smart factories—demonstrate the transformative power of Vertical AI in manufacturing. As these technologies continue to evolve, they will redefine the way manufacturers operate, offering unprecedented levels of efficiency, cost savings, and innovation.

5. Vertical AI Startups in Manufacturing

The rise of Vertical AI in manufacturing is driven by a group of innovative startups that are redefining the way factories operate. These companies are developing tailored AI solutions that directly address the challenges unique to the manufacturing industry, such as optimizing supply chains, ensuring quality control, and increasing equipment uptime. Below are some of the most notable startups, spotlighted by IVP that are leading the way in the transformation of manufacturing through AI.

1. Basetwo

Basetwo is primarily focused on process optimization rather than supply chain management. Their AI-driven platform helps process engineers improve the visibility and performance of manufacturing processes by enabling them to build and operationalize digital twins—virtual models of manufacturing processes. These digital twins are used for real-time analysis, optimization, and validation of various production processes.

Key functionalities include:

- Low-code platform: Basetwo allows engineers to easily integrate data, build machine learning models, and optimize process workflows without extensive coding.

- Real-time process optimization: By analyzing process data, the platform provides AI-driven recommendations that help manufacturers reduce downtime, minimize material usage, and enhance production efficiency.

- Cross-industry applications: Basetwo supports various industries, including pharmaceuticals, energy, aerospace, and consumer packaged goods, offering tailored AI solutions to improve process reliability and sustainability.

By leveraging Basetwo’s platform, companies can reduce energy consumption and material costs, shorten cycle times, and reduce their carbon footprint.

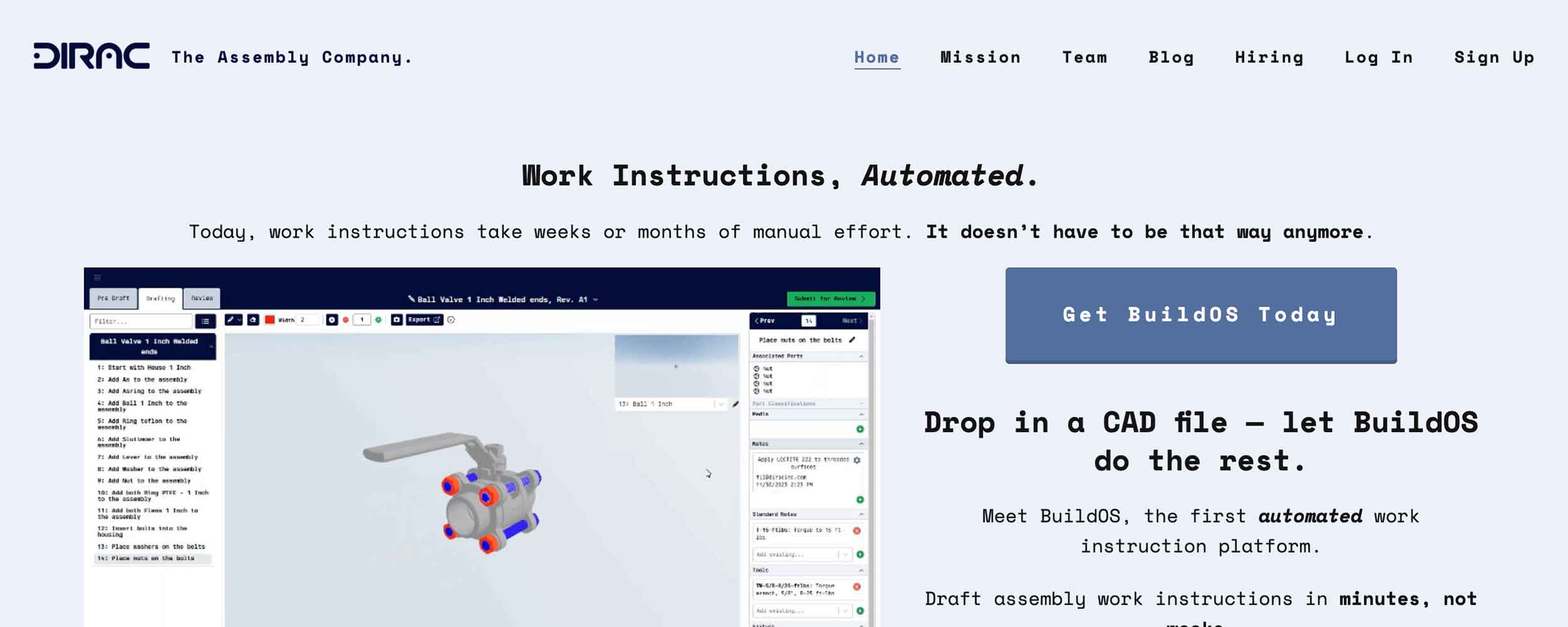

2. Dirac

Dirac is not primarily focused on predictive maintenance. Instead, its core product, BuildOS automates the creation of assembly work instructions. This platform streamlines the traditionally time-consuming process of converting CAD files into step-by-step instructions used on the manufacturing floor.

With BuildOS, users can upload CAD files, and the platform automatically generates the assembly sequence, 3D animations, and text instructions in just a few minutes. The system completes 80% of the work, leaving only the final 20% to human fine-tuning. This approach dramatically reduces the time required to create instructions from days or weeks to just hours, enhancing production speed and reducing human error.

Instead of focusing on maintenance, Dirac’s platform enhances operational efficiency by simplifying the creation of critical production documents, contributing to faster time-to-market and lower production errors. This automation improves the overall manufacturing process by allowing engineers to focus on more value-added tasks.

3. EthonAI

EthonAI specializes in automating quality control processes using AI-powered visual inspection systems. Their flagship product, Inspector, provides real-time defect detection for manufacturers, offering high accuracy in detecting surface defects and assembly errors.

What makes EthonAI’s solution particularly valuable is its ability to train using only defect-free images. This is crucial for manufacturers where collecting a variety of defective images can be difficult or expensive. The Inspector software uses generative algorithms that can reliably detect anomalies with minimal training data, making it highly scalable and adaptable to different production environments. Additionally, the software is hardware-agnostic, meaning it can integrate seamlessly with various industrial camera systems, and is designed for both automated and manual quality inspection setups.

4. Keychain

Keychain a platform designed for the consumer packaged goods (CPG) industry, focusing on optimizing the manufacturing process for brands and retailers. The platform uses AI-driven insights to connect businesses with manufacturing partners that best fit their needs, ensuring more efficient production, better scalability, and faster time-to-market. Keychain simplifies the sourcing of manufacturers, particularly in areas such as packaging and product development, helping companies overcome common supply chain challenges by leveraging tailored solutions that meet their specific product demands.

5. Leucine

Leucine's platform is specifically designed for the pharmaceutical industry, focusing on ensuring quality compliance and manufacturing efficiency. Their system helps companies digitize their production processes, including batch manufacturing records (BMRs) and production logbooks, to ensure regulatory compliance and streamline operations.

Rather than creating IoT-based smart factories as mentioned in the original description, Leucine offers a Manufacturing Execution System (MES) that provides real-time monitoring of production activities, helping companies track batch progress, manage deviations, and maintain FDA compliance. This platform is particularly valuable for industries where strict regulatory standards and precise quality control are critical, such as pharmaceuticals.

Leucine’s solutions also include tools for automating batch record reviews, recipe building, and managing work-in-progress (WIP) inventory. These features allow pharmaceutical companies to achieve faster go-live times for new products, improve compliance, and enhance overall production efficiency.

6. Luminary

Luminary offers a cloud-based platform specializing in computer-aided engineering (CAE) for advanced simulations. It enables engineers to run high-fidelity simulations in a fraction of the time by utilizing scalable cloud-based computing resources. This allows for faster product design, development, and decision-making, particularly in industries like aerospace, automotive, and industrial manufacturing. Luminary’s solutions help companies optimize their engineering processes, reduce the need for physical prototypes, and accelerate digital adoption through AI-driven simulations.

7. MaintainX

MaintainX offers a comprehensive platform for maintenance and operations management. It helps manufacturers digitize their workflows, including maintenance requests, work orders, and inspections, making it easier to track and manage equipment upkeep in real time. With AI-powered asset management, the platform enables companies to increase equipment uptime, reduce operational costs, and improve productivity. MaintainX’s user-friendly interface also supports integration with other enterprise systems, providing manufacturers with seamless, real-time operational insights and improved efficiency.

8. Nominal

Nominal focuses on providing a unified data infrastructure for manufacturers and engineering teams. Rather than specializing solely in production line optimization, Nominal’s platform is designed to help hardware teams analyze and manage high-scale data from development to operations. It integrates real-time observability, data cataloging, and validation workflows, enabling teams to track and act on key metrics across different stages of production and testing.

Nominal’s platform also supports the collaborative development of validation rules, anomaly detection, and historical data analysis, making it ideal for industries with complex machinery and mission-critical processes, such as aerospace, defense, and industrial manufacturing. By synchronizing data from multiple sources and streamlining decision-making processes, Nominal helps companies reduce operational expenses and accelerate their product development cycles.

9. PHYSICSX

PHYSICSX focuses on applying AI and machine learning to optimize physics simulations and engineering processes, particularly in complex and high-demand industries such as aerospace, automotive, renewables, and materials production. Their platform enhances the accuracy of simulations and significantly reduces the time required for product development by leveraging AI to streamline some of the most time-consuming activities in engineering, such as simulation validation and design optimization.

PHYSICSX's solutions are especially valuable for industries where rigorous testing and precision are critical, helping companies improve product performance, reduce development costs, and accelerate the deployment of new technologies. Their AI-powered tools provide insights into how materials and processes will perform under different conditions, enabling more efficient and scalable production across industries such as electric vehicles, wind turbines, and semiconductors

10. SIFT

SIFT is focused on providing a unified observability platform specifically designed for hardware data rather than materials management. Their platform enables companies to manage complex machines by collecting, analyzing, and visualizing data from operational hardware in real time. SIFT’s solutions empower engineering teams with automated data review, anomaly detection, and predictive insights, allowing them to troubleshoot issues faster and improve overall machine performance.

SIFT is particularly beneficial for industries like aerospace, transportation, and complex manufacturing, where monitoring high-frequency sensor data is critical. By reducing the need for manual data review and providing real-time operational insights, SIFT enhances the ability to maintain machine reliability and accelerate innovation.

11. Squint

Squint combines augmented reality (AR) with AI to enhance workforce training and operational efficiency in industrial settings. The platform enables factory workers to access real-time, step-by-step instructions by overlaying digital information directly onto physical environments. Squint’s AR technology helps employees execute complex tasks with greater accuracy and speed, which significantly reduces training time and improves task execution on the shop floor.

A standout feature of Squint is its Video-to-Procedure AI, which allows users to capture a how-to video and automatically convert it into an interactive AR guide. This functionality enables workers to quickly learn complex processes, making training faster and more engaging. Squint's platform is designed for a variety of industries, including automotive, heavy industrials, and energy, where precision and speed are critical to maintaining productivity and safety.

12. TRACTIAN

TRACTIAN provides AI-powered predictive maintenance solutions that monitor the health of factory equipment in real time. Their system includes smart sensors and a maintenance management platform that continuously collects and analyzes data on machinery performance. With this data, TRACTIAN’s AI identifies potential failures before they occur, allowing manufacturers to schedule proactive maintenance. This helps reduce unplanned downtime, extend the lifespan of machinery, and increase overall operational efficiency.

TRACTIAN’s solutions are widely used across industries such as automotive, food & beverage, mining, and consumer goods, where maintaining consistent uptime is crucial. By integrating predictive maintenance with real-time condition monitoring, manufacturers can avoid costly disruptions and improve productivity.

13. VIZCOM

VIZCOM specializes in AI-driven visualization tools that allow designers to transform 2D sketches into 3D models in seconds, significantly speeding up the design and prototyping process. The platform helps designers quickly generate realistic renderings and interactive 3D models from simple sketches, bridging the gap between initial ideas and fully developed visual concepts. This feature is particularly useful in industries that rely on rapid design iteration, such as automotive, consumer electronics, and industrial design.

With Vizcom’s real-time rendering and 3D generation capabilities, designers can visualize their ideas from new angles, apply different materials, and even export their designs for 3D printing or augmented reality (AR) integration. This approach enhances both the speed and creativity of the design process, enabling rapid experimentation and iteration without the need for complex traditional CAD software.

These startups are not only leading the charge in the Vertical AI space but are also fundamentally reshaping the manufacturing landscape. By focusing on industry-specific challenges such as supply chain management, quality control, and equipment maintenance, they are enabling manufacturers to achieve new levels of efficiency, precision, and competitiveness. Through the innovative use of AI, these companies are paving the way for the future of manufacturing.

6. Benefits of Vertical AI for Manufacturing

Vertical AI is revolutionizing the manufacturing sector, providing tailored solutions that address the industry's specific needs and challenges. Below are some key benefits that highlight the value of Vertical AI in transforming manufacturing operations:

1. Increased Operational Efficiency

Vertical AI plays a critical role in improving operational efficiency by automating repetitive tasks and optimizing complex workflows. AI-driven systems can process vast amounts of data in real-time, enabling factories to monitor equipment performance and identify inefficiencies. Predictive maintenance powered by AI helps manufacturers anticipate machinery failures, reducing costly downtime and extending equipment lifespan. Additionally, tools like MaintainX help manufacturers digitize workflows, improving task management and operational visibility.

2. Enhanced Product Quality

By utilizing AI-driven precision and real-time monitoring, manufacturers can significantly improve product quality. Automated quality control systems, such as those developed by EthonAI, enable faster and more accurate detection of defects during production. These AI systems can identify anomalies that human inspectors might miss, leading to higher accuracy, consistency, and fewer defective products. The ability to maintain stringent quality standards is especially valuable in industries like pharmaceuticals and automotive.

3. Cost Reduction

Vertical AI helps reduce operational costs by minimizing waste, optimizing supply chains, and improving energy efficiency. AI platforms such as Basetwo and Nominal enable manufacturers to optimize material usage, streamline workflows, and reduce resource consumption, which leads to significant cost savings. AI also helps with just-in-time inventory management, reducing the likelihood of overstocking or material shortages. Predictive analytics also ensure that equipment is maintained before failures occur, preventing expensive repairs or replacements.

4. Faster Time-to-Market

AI accelerates product development by automating the design and prototyping processes. Tools like Vizcom enable designers to quickly convert 2D sketches into 3D models, allowing for rapid iterations and reducing the time required for product design. AI-driven platforms provide real-time insights, allowing manufacturers to adapt to market demands and adjust production schedules efficiently. This agility allows companies to bring new products to market faster while maintaining flexibility in responding to customer needs.

7. Challenges Facing Vertical AI Startups in Manufacturing

As promising as Vertical AI is for revolutionizing the manufacturing industry, startups in this space face several significant challenges. These hurdles can impede the seamless integration and scalability of AI technologies across manufacturing environments. Below are the key challenges these startups encounter:

1. Integration with Legacy Systems

One of the most pressing challenges for Vertical AI startups in manufacturing is integrating their AI solutions with the legacy systems that many manufacturing companies still use. Legacy systems are often outdated, incompatible with modern AI software, and highly customized, making it difficult to introduce new technologies. Startups must build AI tools that can work alongside or replace these older systems without disrupting the existing infrastructure.

For example, many manufacturing plants continue to rely on decades-old programmable logic controllers (PLCs) and enterprise resource planning (ERP) systems, which were not designed to accommodate AI-driven automation or predictive maintenance technologies. The process of retrofitting such systems can be costly and time-consuming, requiring significant investment from manufacturers and the development of flexible solutions from AI startups.

2. Data Security and Privacy

With increased digitization and interconnected systems, the risk of data breaches and unauthorized access to sensitive operational data is a growing concern. Manufacturing companies handle large volumes of proprietary data related to production processes, intellectual property, and supply chain management, which makes them prime targets for cyberattacks.

For Vertical AI startups, ensuring data security and complying with data privacy regulations like GDPR or CCPA is a significant challenge. AI solutions must be designed with built-in security protocols to prevent breaches, while also ensuring that sensitive operational data remains secure during analysis and processing. This concern is even more pronounced for manufacturers operating across multiple regions, where different regulations apply.

3. Scalability

Scaling AI solutions across multiple factories and regions presents another key challenge. While AI models might perform well in a single factory or environment, expanding their use across a global manufacturing network introduces complexity. Factories in different regions often have unique workflows, varying levels of automation, and disparate data infrastructures, which can hinder the seamless deployment of AI tools.

Startups like TRACTIAN and SIFT have developed predictive maintenance tools that can analyze equipment data in real time, but ensuring that these solutions can be deployed at scale requires significant customization and operational changes across different sites. Moreover, scaling AI across multiple plants involves large volumes of data, complex machine learning models, and robust computing infrastructure, which can be difficult to standardize.

8. The Future of Vertical AI in Manufacturing

As the manufacturing sector becomes increasingly reliant on data-driven decision-making and automation, Vertical AI is positioned to play a transformative role in shaping the future of production. By combining the power of AI, robotics, and IoT, manufacturers can achieve new levels of efficiency and responsiveness. Below are some key trends that will define the future of Vertical AI in manufacturing:

1. Hyperautomation and Decision Intelligence

The concept of hyperautomation—where AI systems automate nearly all repetitive and rule-based tasks—is set to revolutionize manufacturing. Hyperautomation extends beyond just automating individual processes to creating interconnected systems that can continuously optimize themselves. Vertical AI platforms, like TRACTIAN for predictive maintenance, will work in tandem with decision intelligence systems that enable manufacturers to make smarter, faster decisions based on real-time data.

Decision intelligence goes beyond conventional analytics by using machine learning models to simulate different scenarios, predict outcomes, and provide actionable insights. As more manufacturers adopt AI-driven decision intelligence, they will be able to respond to complex operational challenges in real time, improving resource allocation, reducing waste, and maximizing equipment uptime.

2. Autonomous Manufacturing

The integration of robotics with AI and IoT is paving the way for autonomous manufacturing, where factories will have the ability to operate with minimal human intervention. AI-powered robots will perform a wide range of tasks, from assembly to quality control, with increasing precision and adaptability. Startups like Dirac and Leucine are already working on integrating these advanced AI solutions into existing factory infrastructures, helping manufacturers transition towards fully autonomous production lines.

This shift will lead to the rise of lights-out factories, where entire facilities are run without human oversight. This concept is particularly advantageous in industries like semiconductors, aerospace, and automotive, where precision, consistency, and speed are paramount. Autonomous manufacturing will also help companies scale operations quickly and cost-effectively, providing a critical advantage in an increasingly competitive global market.

3. AI-Driven Robotics and IoT Integration

The future of manufacturing will be defined by the convergence of AI, robotics, and IoT (Internet of Things). As IoT devices become more prevalent on the factory floor, the data generated by these devices will fuel AI models that can optimize workflows, predict equipment failures, and provide real-time feedback on production conditions.

Startups like PHYSICSX are working on AI-driven simulations that can enhance the performance of industrial robotics by optimizing their interactions with other machines and systems. These simulations reduce the need for extensive physical testing, accelerating product development and improving system efficiency. By integrating robotics and IoT with AI, manufacturers can achieve smart factories, where every machine, device, and system is interconnected and capable of real-time communication and decision-making.

4. Enhanced Customization and Flexibility

Vertical AI will also drive a future where manufacturing becomes more customized and flexible. Using AI to analyze consumer trends and production data, manufacturers will be able to quickly adjust production lines to meet shifting demand. This approach allows for more personalized manufacturing, where products can be tailored to specific customer preferences at scale. AI will also enable on-demand production, which reduces inventory and increases agility in industries like consumer electronics and automotive.

The ability to adapt to changing market conditions will be key to staying competitive in a global marketplace. By using AI to streamline operations and enhance flexibility, manufacturers can quickly pivot to new opportunities, create bespoke products, and enter new markets with reduced lead times.

The future of Vertical AI in manufacturing is characterized by hyperautomation, autonomous factories, and the seamless integration of AI, robotics, and IoT. These advancements will not only improve operational efficiency but also enable manufacturers to achieve new levels of precision, customization, and speed. By adopting these AI-driven innovations, manufacturers can future-proof their operations, ensuring they remain competitive in an increasingly automated and data-driven world.

Conclusion

The transformative potential of Vertical AI in manufacturing cannot be overstated. As more manufacturers adopt AI-driven solutions, the sector stands at the cusp of a new industrial revolution—one defined by hyperautomation, autonomous systems, and real-time data analytics. The ability of Vertical AI startups to provide tailored solutions for specific manufacturing challenges, such as predictive maintenance, supply chain optimization, and quality control, is reshaping the way products are designed, produced, and delivered to market.

Startups like TRACTIAN, EthonAI, and Vizcom exemplify how AI can revolutionize not only efficiency but also product quality and development speed. By automating routine tasks and enabling decision intelligence, these technologies empower manufacturers to operate with greater precision and adaptability. The rise of smart factories that seamlessly integrate IoT, AI, and robotics is already underway, and manufacturers that embrace these innovations will have a significant competitive edge in the global market.

However, navigating challenges such as data security, scalability, and the integration of AI with legacy systems remains critical. As manufacturers address these hurdles, the potential for Vertical AI to drive the next wave of industrial innovation becomes even clearer.

In conclusion, the time is now for manufacturing companies to explore AI partnerships and leverage the expertise of startups leading the charge in Vertical AI. By doing so, they will not only future-proof their operations but also unlock new avenues for growth, efficiency, and innovation.

References

- IVP | The Value of Vertical AI

- Giselles AI | Vertical AI Industry Solutions

- Cowboy Ventures | Modernizing the Manufacturing Industry with AI

- TechCrunch | Vertical AI: The Next Logical Iteration of Vertical SaaS

- BVP | The Future of AI is Vertical

Please Note: This content was created with AI assistance. While we strive for accuracy, the information provided may not always be current or complete. We periodically update our articles, but recent developments may not be reflected immediately. This material is intended for general informational purposes and should not be considered as professional advice. We do not assume liability for any inaccuracies or omissions. For critical matters, please consult authoritative sources or relevant experts. We appreciate your understanding.