The global supply chain and logistics industry is facing unprecedented complexity and challenges. One of the biggest hurdles is inefficient tracking across global supply chains, often due to reliance on outdated systems lacking real-time visibility. These inefficiencies lead to delays, errors, and costly disruptions, at a time when consumer demand for faster and more reliable delivery services continues to rise. E-commerce has further raised the stakes, with expectations for same-day and next-day delivery putting significant pressure on logistics providers to optimize operations.

Compounding this, businesses are grappling with rising operational costs driven by fluctuating fuel prices, labor shortages, and mounting regulatory demands. As these challenges intensify, companies must adopt transformative technologies to maintain competitiveness in this dynamic environment. This is where AI technologies, particularly Vertical AI, offer critical solutions by streamlining processes, improving decision-making, and boosting overall efficiency.

The Rise of Vertical AI in Supply Chain & Logistics

Vertical AI solutions, unlike general-purpose AI, are tailored to address specific industry challenges, and logistics is a prime beneficiary. These AI tools harness domain-specific expertise to tackle problems like optimizing inventory, enhancing route planning, and automating warehouse tasks. Vertical AI systems, designed with a deep understanding of the logistics sector, provide sharper insights and more actionable outcomes than generalized AI.

In supply chain management, Vertical AI offers significant improvements across multiple touchpoints—from real-time inventory monitoring to predictive maintenance and dynamic routing optimization. These AI-driven tools enable businesses to streamline operations, cut operational costs, and make faster decisions. The tailored nature of Vertical AI makes it especially effective in logistics, where speed, precision, and adaptability are crucial for maintaining a competitive edge.

Key Applications of AI in Supply Chain & Logistics

Inventory Management Optimization

Inventory management is a core component of supply chain operations, but traditional methods often lack the accuracy to match fluctuating demand. AI has transformed this space by integrating predictive analytics, allowing companies to optimize stock levels in real time. Machine learning algorithms analyze historical sales data, market trends, and consumer behavior, helping companies avoid overstocking and stockouts—thereby minimizing waste and maximizing capital efficiency.

AI-Powered Route Optimization

The complexities of global supply chains make route optimization a persistent challenge. AI-powered tools can analyze real-time data such as GPS information, weather patterns, and traffic conditions to create more efficient routes. This dynamic adjustment leads to faster deliveries and reduced fuel consumption, benefiting both the environment and the bottom line.

Predictive Maintenance

AI-based predictive maintenance tools are increasingly important in logistics, where equipment uptime is critical. These tools use sensor data to monitor vehicle and machinery performance, predicting failures before they happen and enabling timely interventions. This not only minimizes costly breakdowns but also ensures smoother operations across the supply chain.

Automation in Warehousing

Warehouse automation, powered by AI, is becoming essential for businesses dealing with high order volumes, particularly during peak seasons. AI-driven robots can handle tasks like sorting, picking, and packing with higher speed and accuracy, significantly reducing labor costs while ensuring faster order fulfillment.

Leading Vertical AI Startups in Supply Chain & Logistics

Several pioneering startups are transforming supply chain and logistics through AI, offering specialized solutions to address the sector's unique challenges. These startups, many of which are featured by IVP, are leading the way in driving operational efficiency and scalability.

DIDERO

DIDERO is a platform designed to revolutionize supply chain management by leveraging artificial intelligence. Its mission is to make global trade as seamless as local transactions, focusing on optimizing business processes within supply chains. The platform integrates AI technologies to help businesses manage their operations more efficiently, including analytics for performance tracking, customer support, and technical issue resolution.

Didero's platform also provides subscription-based services, allowing users to access advanced tools for supply chain management. They utilize AI to monitor usage, analyze data, and offer insights that drive operational improvements, all while maintaining strong data privacy and security protocols.

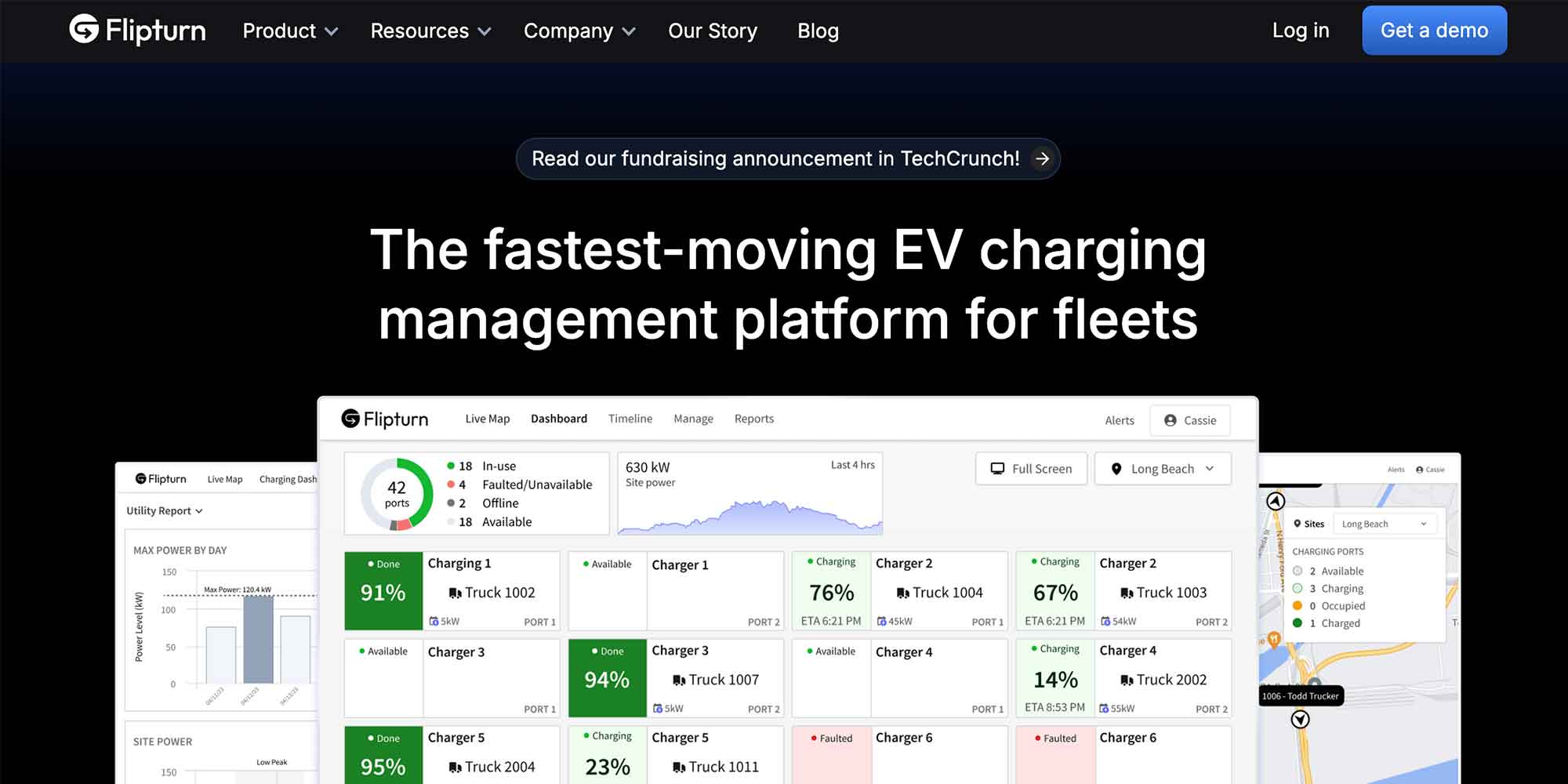

Flipturn

Flipturn is an AI-powered platform designed to manage EV fleet charging operations efficiently. It helps businesses monitor and optimize their electric vehicle (EV) chargers and fleets by providing real-time visibility into charging performance, diagnosing issues, and sending timely alerts. The platform offers features like dynamic power management, charging time estimates based on historical data, and detailed reporting on metrics such as cost per mile and range prediction. By integrating with systems like Geotab, Flipturn enables fleets to minimize utility costs, improve charger uptime, and ensure vehicles are always ready on time.

Flipturn is widely used by organizations such as Zeem Solutions and Forum Mobility, helping them scale their EV operations effectively. It also provides tools for automated billing and fleet energy management, making it a comprehensive solution for both large and small fleet operators.

FLEETWORKS

FLEETWORKS, a Y Combinator-backed startup, is focused on automating logistics operations using AI. The platform acts as a virtual assistant for freight brokers, automating tasks like vetting carriers, answering queries, and negotiating rates for posted loads. With its AI-powered automation, FleetWorks aims to help logistics companies scale more efficiently by reducing operational overhead and ensuring timely communication with carriers.

FleetWorks integrates seamlessly with existing logistics systems, allowing companies to manage operations more effectively without needing extensive manual intervention. The platform has gained recognition and trust from leading brokers and logistics firms, helping streamline communications and enhance decision-making in real time.

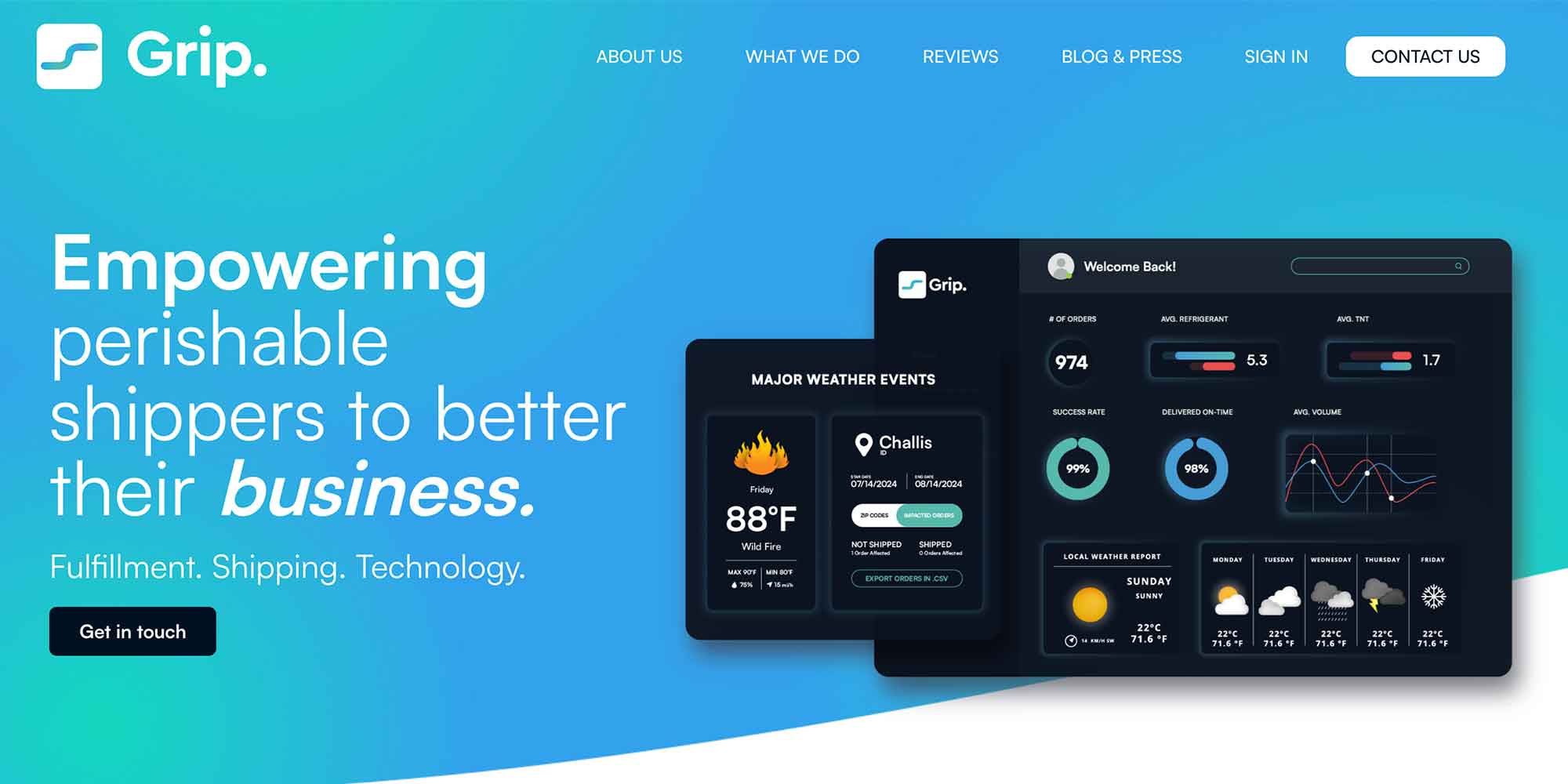

Grip

Grip is an AI-powered logistics platform specifically designed for perishable eCommerce brands. It optimizes the shipping and fulfillment process by analyzing real-time data to reduce shipping costs and minimize failures, particularly for goods like frozen foods, pharmaceuticals, and flowers. Grip’s Smart Logistics Engine helps companies by determining the most efficient packaging, shipping routes, and carriers based on factors such as package size, destination, and real-time weather conditions. This allows brands to save on shipping costs and reduce spoilage, with the platform helping customers lower costs by up to 30% and reduce shipping failures by 25%.

Grip’s Pulse dashboard, their Order Management System (OMS), provides brands with real-time insights into their inventory, shipping performance, and refrigerant usage. It integrates seamlessly with platforms like Shopify, enabling brands to monitor inventory and shipments in one place. Additionally, Grip operates nationwide fulfillment centers, allowing for fast and efficient deliveries within 24 to 48 hours across the U.S.

HAPPYROBOT

HAPPYROBOT, a Y Combinator-backed startup, develops AI-powered voice agents that automate phone calls for logistics and fleet enterprises. Their technology helps businesses streamline tasks such as carrier sales, load updates, check calls, and appointment scheduling through AI-driven phone conversations. The platform integrates seamlessly with existing systems like Transportation Management Systems (TMS), ensuring smooth operations without manual intervention. These AI agents can handle both inbound and outbound calls, offering features such as intent detection, live transcripts, and real-time analytics to enhance operational efficiency.

Happyrobot's AI solutions are highly customizable, allowing logistics companies to personalize voice assistants or even clone existing team members' voices. Trusted by numerous logistics and freight companies, Happyrobot aims to reduce operational overhead and improve customer satisfaction by automating routine call-based tasks.

Pallet

Pallet is an AI-powered logistics platform that provides an all-in-one solution for managing transportation and warehouse operations. The platform integrates key features such as Transportation Management Systems (TMS), Warehouse Management Systems (WMS), billing, order fulfillment, and real-time customer communication. By centralizing these functions, Pallet helps logistics companies automate tasks like order entry, scheduling, invoicing, and dispatch, streamlining workflows to increase efficiency.

Pallet also offers AI-driven automation to reduce manual workloads, including real-time tracking and automated appointment scheduling. Its seamless integration with enterprise systems and advanced tools like EDI and API ensure modern logistics operations can run smoothly. The platform is designed to serve cartage agents, distributors, and third-party logistics providers, helping them reduce costs and improve operational efficiency.

Benefits of Adopting Vertical AI in Supply Chain & Logistics

Increased Efficiency and Cost Reduction

Vertical AI solutions bring remarkable improvements in both efficiency and cost management by automating repetitive tasks and providing advanced, data-driven decision-making capabilities. Tasks such as route optimization, inventory management, and warehouse operations can now be automated using AI, reducing manual intervention and minimizing human error. For instance, AI-driven systems like those from Flipturn help logistics companies prevent overstocking and minimize excess inventory, cutting storage costs and waste.

AI-powered route optimization tools, such as those offered by FLEETWORKS, dynamically adjust delivery routes in real time by analyzing GPS data, weather conditions, and traffic patterns. These tools help reduce fuel consumption and transportation costs while ensuring faster deliveries. Over time, these incremental improvements lead to significant cost savings, making AI essential for maintaining competitiveness in a margin-sensitive industry.

Improved Decision-Making with Real-Time Data

One of the most profound benefits of adopting AI in supply chain and logistics is the enhanced ability to make real-time, informed decisions. AI platforms continuously collect and analyze data from multiple points along the supply chain, offering actionable insights that enable companies to adapt quickly to changing circumstances. Whether it's adjusting inventory levels in response to demand fluctuations or rerouting deliveries due to unforeseen delays, AI-powered systems allow logistics managers to make smarter, faster decisions.

For example, Grip’s AI platform uses predictive analytics to suggest optimal shipping methods based on historical data and real-time conditions. By leveraging these insights, businesses can minimize delivery delays, improve accuracy, and maintain high levels of customer satisfaction. This increased agility allows companies to stay ahead of competitors by rapidly adapting to market changes and improving service reliability.

Scalability and Flexibility

Another major advantage of Vertical AI is its scalability. As companies expand, AI solutions can scale seamlessly to handle larger volumes of data and operations without the need for significant increases in labor or infrastructure. For instance, Pallet’s AI-powered warehouse automation system can grow alongside a company, allowing it to handle increasing order volumes without additional labor costs.

Furthermore, AI offers the flexibility to adapt to sudden changes in market demand or supply chain disruptions. With AI tools that continuously learn and improve, logistics companies can maintain efficiency even in the face of unpredictable challenges. This flexibility ensures that businesses remain resilient and capable of meeting evolving customer expectations, even during times of volatility.

Challenges of Implementing AI in Supply Chain & Logistics

Data Integration Issues

Despite the many benefits of AI, there are significant challenges in implementing these technologies, particularly around data integration. Many logistics companies still rely on legacy systems that were not designed to integrate with modern AI platforms. These systems often create data silos, making it difficult to achieve the seamless data flow necessary for AI to function effectively.

Integrating data from outdated enterprise resource planning (ERP) systems with AI-powered logistics platforms can be a time-consuming and costly process. Companies must standardize their data and modernize their infrastructure to fully unlock the potential of AI. DIDERO, for example, addresses this challenge by developing AI tools that bridge the gap between old and new systems, enabling companies to leverage AI without completely overhauling their existing infrastructure.

Security and Privacy Concerns

As AI becomes more embedded in supply chain operations, concerns around data security and privacy grow. AI systems rely on large volumes of data, much of which is sensitive, such as customer information, shipment details, and financial records. This makes the supply chain a prime target for cyber-attacks.

AI also introduces new risks by automating critical decision-making processes. If compromised, these systems could be manipulated, leading to delays, inventory shortages, or financial losses. Companies like HAPPYROBOT prioritize data security by implementing robust cybersecurity measures and adhering to data protection regulations such as the General Data Protection Regulation (GDPR). Partnering with AI providers that emphasize transparency and security can help businesses mitigate these risks.

The Future of AI in Supply Chain & Logistics

AI-Driven Autonomous Logistics

The logistics industry is on the cusp of a major transformation with the rise of AI-driven autonomous systems. Autonomous vehicles and drones are set to play an increasingly important role in last-mile deliveries. Major companies like Amazon and FedEx are already testing autonomous delivery vehicles, which promise to reduce human error, lower operational costs, and increase delivery speeds.

In addition to autonomous delivery, AI is reshaping warehouse operations with smart warehouses that leverage robotics, AI-powered systems, and IoT sensors. These smart warehouses automate sorting, picking, and packing processes, allowing for faster and more accurate operations with minimal human intervention. As these technologies evolve, we can expect to see warehouses becoming fully autonomous, with AI driving all aspects of logistics operations.

Hyperautomation in Supply Chain

Hyperautomation, the combination of AI, machine learning, and robotic process automation (RPA), is emerging as a key trend in logistics. Hyperautomation goes beyond task automation to enable end-to-end automation of complex workflows. In the supply chain, this means automating everything from order processing to shipment tracking and customer service.

AI-powered hyperautomation allows businesses to streamline operations, improve accuracy, and make data-driven decisions in real-time. As logistics providers embrace this trend, they will be able to scale more effectively, reduce operational costs, and respond more quickly to market changes. Hyperautomation represents the next frontier in supply chain management, enabling companies to operate with unprecedented efficiency and agility.

Conclusion

Vertical AI is revolutionizing the supply chain and logistics industry by addressing key challenges such as inefficiencies in tracking, high operational costs, and the increasing demand for faster, more reliable deliveries. By adopting AI-powered solutions, businesses are not only enhancing operational efficiency but also improving decision-making through real-time data insights.

The impact of AI goes far beyond automation—it enables companies to scale their operations, respond to market changes with agility, and build self-optimizing systems that enhance resilience and competitiveness. Startups like DIDERO, Flipturn, FLEETWORKS, Grip, HAPPYROBOT, and Pallet are leading the charge, providing specialized AI tools that are helping logistics companies stay ahead in an increasingly complex environment.

As AI technologies continue to evolve, businesses that invest in Vertical AI solutions will have a significant advantage in navigating the complexities of the modern supply chain. The future of logistics is intelligent, data-driven, and highly automated, and companies that embrace these innovations today will be the leaders of tomorrow.

References

- IVP | The Value of Vertical AI

- EETimes | Supply Chain Industry Is Being Shaped by AI

- Bain Capital Ventures | How Generative AI Is Reinventing Freight Logistics Technology

- KPMG | Supply Chain Trends 2024

- MIT Sloan | How Artificial Intelligence is Transforming Logistics

- Giselles | Vertical AI Startups: IVP Manufacturing

- Y Combinator | FLEETWORKS

- Y Combinator | HAPPYROBOT

- TechCrunch | Pallet Uses AI to Bring Logistics Into the 21st Century

Please Note: This content was created with AI assistance. While we strive for accuracy, the information provided may not always be current or complete. We periodically update our articles, but recent developments may not be reflected immediately. This material is intended for general informational purposes and should not be considered as professional advice. We do not assume liability for any inaccuracies or omissions. For critical matters, please consult authoritative sources or relevant experts. We appreciate your understanding.